Project Objective

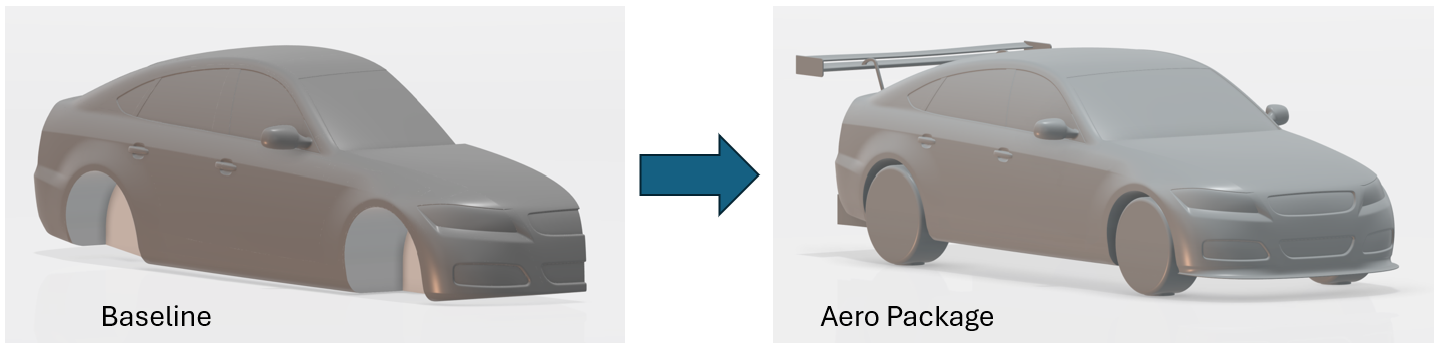

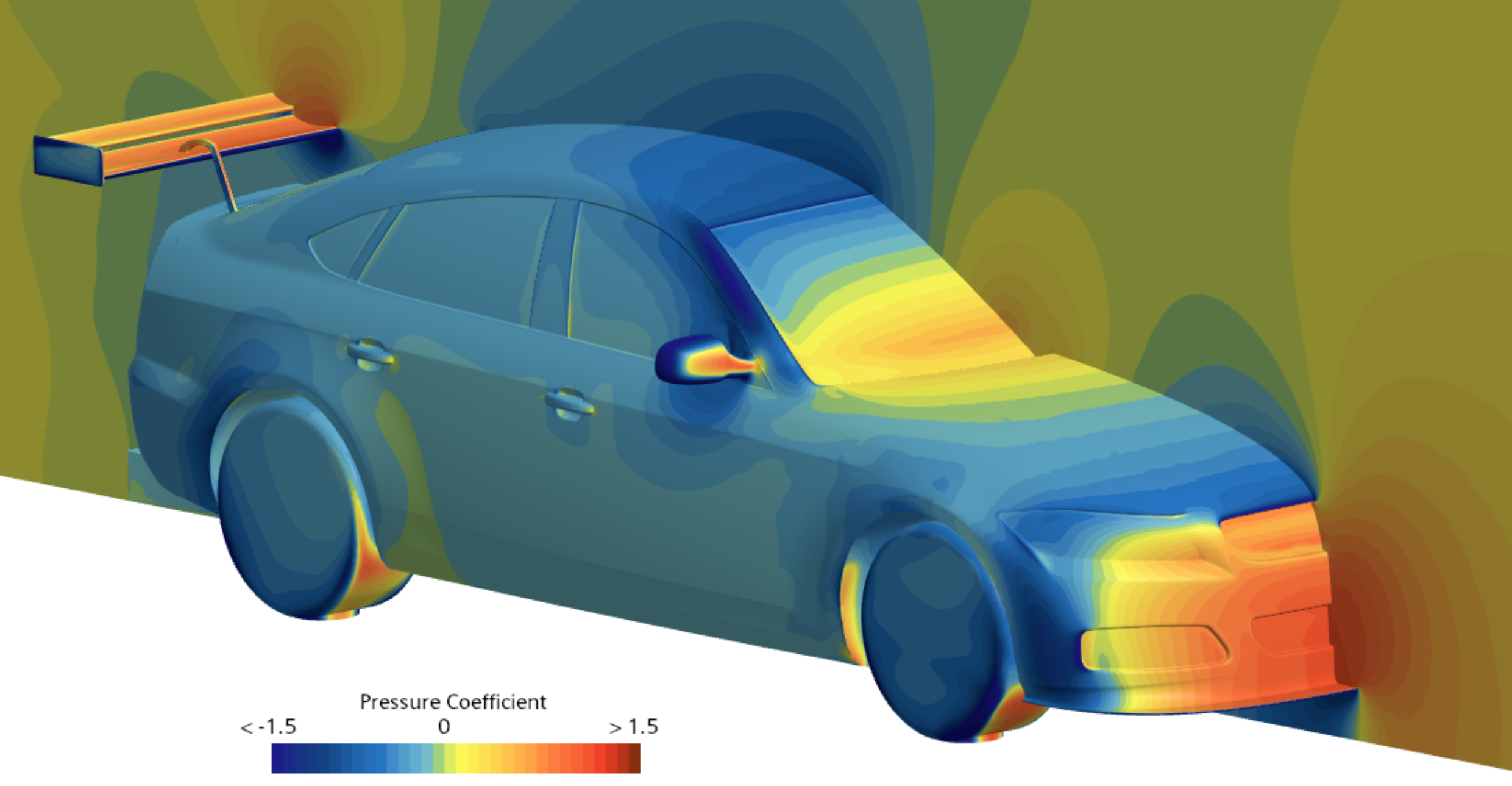

The aim of this project was to perform a comprehensive CFD study of the Drivaer fastback model and design a high-performance aerodynamic package. This involved optimizing key components including the rear wing, diffuser, and front splitter to maximize downforce while minimizing drag.

Methodology Overview

The project followed a systematic approach combining computational fluid dynamics (CFD) simulations with CAD design iterations. Each component was analyzed individually and then integrated into the complete vehicle package for final optimization.

Project Overview

Technology Stack

Description

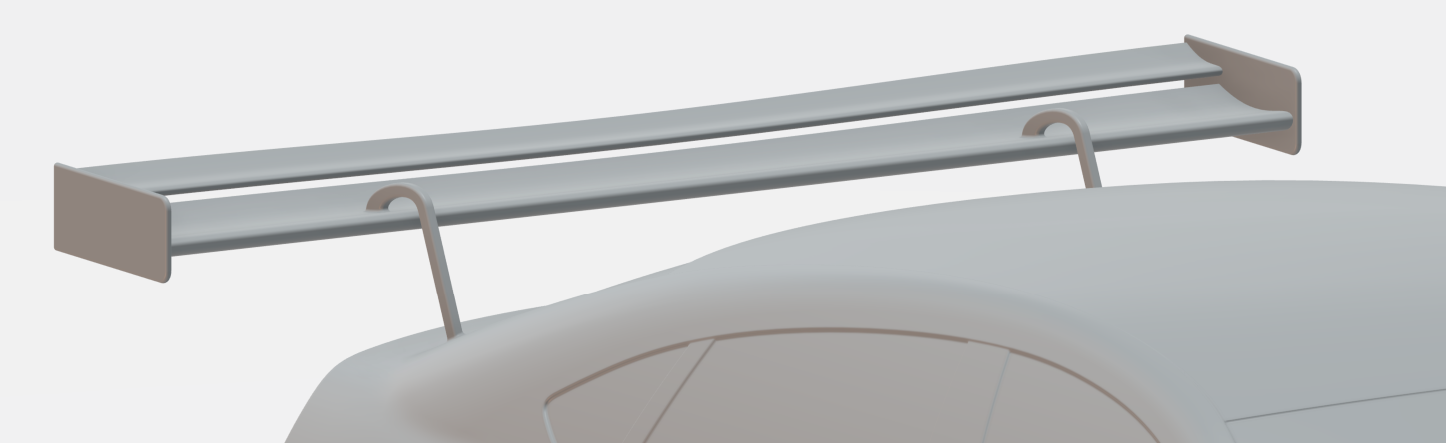

The rear wing was designed to provide high rear downforce for high-speed stability while maintaining aerodynamic efficiency. Multiple wing profiles and angles were tested to achieve the best balance between performance and drag.

CAD Design

Key Technical Outcomes

Description

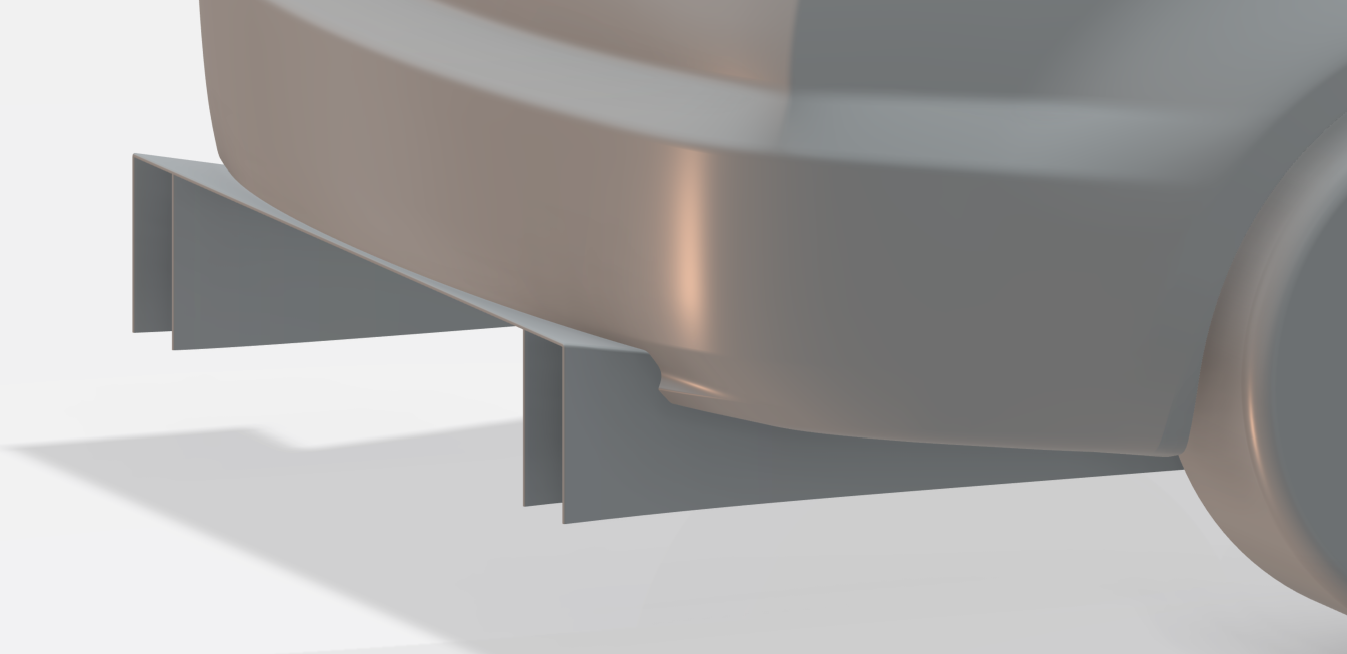

The underbody diffuser was designed to maximize ground effect and create additional downforce through pressure recovery. The CAD design allows to rapidly test diffuser angles and the geometry of the vertical fins.

CAD Design

Key Technical Outcomes

Description

The front splitter was engineered to create a high pressure zone at the airdam and a lower region at the floor increasing front downforce.

CAD Design